I-extruded aluminium - ifuna ubuchwepheshe be-weihua [abahlinzeki be-aluminium extrusion ngokwezifiso] iminyaka engaphezu kwengu-10 yokuhlangenwe nakho okwenziwe ngokwezifiso. I-Miniature aluminium extrusion, i-golden aluminium extrusion, inqubo ephezulu ye-extrusion, abakhiqizi bokuthengisa okuqondile, ikhwalithi yomkhiqizo, wamukelekile ukubonisana!

Iyini inqubo yokucubungula kokuvalelwa kwe-aluminium yensimbi ephathekayo?

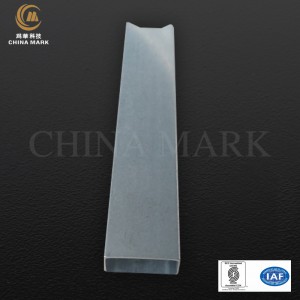

1. I-Aluminium extrusion

Isinyathelo sokuqala ukusika nokukhipha i-aluminium eyindilinga, inqubo eyaziwa njenge-aluminium extrusion, eyenza i-aluminium ekhishwe ibe yishidi elingu-10mm okulula ukulicubungula futhi libe likhulu futhi kube nzima.Lona umsebenzi odinga ukusebenza kwesikhunta se-extrusion.

2. I-DDG

Ithuluzi lomshini we-CNC (ukubhoboza ngesivinini esikhulu nokuthinta isikhungo) lisetshenziselwe ukugaya ngokunembile ishidi le-aluminium libe yivolumu ehleleke kathathu ka-152.2 × 86.1 × 10mm nge-DDG ukwenza lula ukuqeda kwe-CNC okulandelayo.Le nqubo iqala ngokusetshenziswa kwamathuluzi e-carbide ukusebenza.CNC carbide tool

3. Rough Milling umgodi elingaphakathi

Ukuze kube lula ukwenza imishini ye-CNC, umzimba wensimbi uboshwe ngocingo lwasodongeni.Ukugaya umgodi wangaphakathi, umgodi wangaphakathi, kanye nekholomu yokuma kuhlanganiswe nokucubungula okulungiselelwe, okubalulekile ekuxhumaneni okulandelayo kokuxhumanisa.

4. Ukugaya izikhala ze-antenna

Ezingcingo ezinensimbi yonke, inkinga enzima kakhulu ukuxazulula inkinga yesiginali, nayo eyadalwa yisiginali engemihle eyabangelwa ifreyimu yensimbi ngenkathi i-iPhone 4 yethulwa okokuqala. I-Aluminium ibuye ivimbe (yenze buthakathaka) isignali yamaza omsakazo wefoni, ngakho-ke kufanele ifakwe ukuze isignali ibe nendlela engena nephumayo.Ngakho-ke, ukugaya i-antenna slot yisona esibaluleke kakhulu, isinyathelo esinzima kunazo zonke, i-antenna slot kufanele igaye ngokulingana, futhi igcine amaphuzu wokuxhumanisa adingekayo ukuqinisekisa ukuthi amandla nobuqotho begobolondo lensimbi.

5. Isibambo

Ngemuva kokugaya izikhala ze-antenna, "ukwelashwa kwe-T" kusetshenziselwa ukwelapha i-aluminium ngaphezulu okungahlanganiswa namapulasitiki obunjiniyela. Umzimba wensimbi udinga ukufakwa kumakhemikhali akhethekile, njenge-liquid T, ukwakha i-nanoscale (1 nanometer = 10 ^ -9 metres) izimbobo ebusweni be-aluminium, ukulungiselela umjovo olandelayo we-nanoscale.

6.NMT nano umjovo udini

Inqubo "yomjovo wokubumba" ivumela inqubo yokubumba yenaliti ye-NMT ukuthi isetshenziswe ngenxa yomzimba wensimbi ophathwe yi-T.NMT nano injection molding ukukhama ipulasitiki ekhethekile ngaphansi kokushisa okuphezulu nokucindezela okuphezulu ezintweni zensimbi ngemuva kokwelashwa kwe-T, ngakho ukuthi ipulasitiki kanye nobuso bensimbi yemigodi emincane ye-nanoscale buhlanganiswe buqinile, ukuze kufezekiswe inhloso yokuqinisa i-antenna.

7. Qedela indawo yokugaya ekhethiwe

Ngamafoni wonke anensimbi, ngaphezu kwe-antenna yesiginali, kukhona ukwakheka kwe-3D komzimba wensimbi, okuyinqubo edla isikhathi kakhulu, ethatha ngaphezu kwamasekhondi ayi-1 000.

8. Qedela uhlangothi lokugaya

Abangane abaqaphile bangabona ukuthi indawo enamakhasi ayi-3D yomzimba wensimbi ibilokhu igaywa yi-CNC, kepha kusekhona isiyingi sokudilizwa emaphethelweni, esidinga ukugaya ohlangothini ngokunembile, bese uyabona isibonelo sensimbi igobolondo.

9. Ukupholisha

Ngaphambi kokusetshenziswa kwamathuluzi omshini we-CNC asezingeni eliphezulu kakhulu, kepha futhi angafeza kuphela ukuqedwa kwekilasi le-A1 ~ A2, ukuhlangabezana nezidingo zokucubungula ezalandela, idinga ukupholishwa ukuqedwa kwesigaba se-A0, kungaba nomphumela wesibuko.

10. Sandblasting

Kodwa-ke, ifoni eyinsimbi yonke ayinamphumela wokucwebezela ngokugcwele, kepha iveza indawo efriziwe.Lokhu kudinga inqubo "yokuvikela isihlabathi" ukuphatha indawo yensimbi ibe nomphumela wokuthwathwa.

11. Anode munye

I-Aluminium alloy izinzile, ukuze ingaphazanyiswa yizinto zangaphandle ezinjengomjuluko, kufanele ifakwe anodized.Kuyinqubo yokufaka umbala ocingweni, eguqula umbala we-aluminium ube yigolide ngokusebenzisa i-anodizing.Kunzima kakhulu ukulawula inqubo yokudaya i-aluminium alloy, umehluko wombala, amabala azovela uma ukulawulwa kungalungile, okuzophinde kunciphise isivuno.

12. Gqamisa ukwelashwa

Idizayini yokusika enqenqemeni idinga ukusika amakhona kusetshenziswa ibanga eliphakeme kakhulu lemishini ye-CNC ene-ultra-high, inqubo eyaziwa nangokuthi ukubhola noma ukugqamisa.

13. Qeda ukugaya umgodi wangaphakathi

Ngemuva kwezinyathelo eziyi-12 zokucubungula, igobolondo lensimbi seliqalile ukubona ukuvela, khona-ke lizosetshenziselwa ukucindezela ikholomu yokubeka indawo nokunye okweqile kususwe, vumela igobolondo lensimbi ngaphakathi lihlanzeke ngokuphelele.

14. I-anode yesibili

Igobolondo, elicutshungulwe yi-CNC, lidinga ukwelashwa okwesibili kwe-anodic ukuze lenze i-oxidize ingaphezulu futhi lenze ifilimu elicinene nelilukhuni le-oxide, eliyenze imelane nokugqokwa futhi kungabi lula ukulichaphaza.

15. Ukugaya i-conductive bit

Ngemuva kokufakwa kwe-anodic kwe-aluminium ingxubevange yegobolondo ukusebenza kuzoba kubi kakhulu, ngakho-ke kuyadingeka ukuthi kususwe ifilimu lendawo ye-anodic oxidation, insimbi eveziwe ukuthola umphumela omuhle wokuqinisa, futhi kudingeka udlule ku-milling conductive bit of CNC processing.

16.Hot ancibilike nut

Ekugcineni, umuthi wenhlangano ushumekwe kupulasitiki ophelile ngengalo eyirobhothi ukuqinisekisa ukuhlangana okuzayo kwezindawo ezivalekile ze-aluminium yocingo.