Inqubo ye-Aluminium extrusion

Inqubo ye-aluminium alloy extrusion empeleni iqala ngokwakhiwa komkhiqizo, ngoba ukwakheka komkhiqizo kusekelwe kuzidingo zokusetshenziswa ezinikeziwe, ezinquma amapharamitha amaningi wokugcina womkhiqizo.Njengokusebenza kokusebenza komkhiqizo, ukusebenza kwendawo yokwelashwa kanye nokusetshenziswa kwezidingo zemvelo , lezi zakhiwo nezidingo empeleni zinquma ukukhethwa kwe-aluminium alloy extruded.

Kodwa-ke, izakhiwo ze-aluminium ekhishiwe zinqunywa ukwakheka komkhiqizo.Ukuma komkhiqizo kunquma ukwakheka kwe-extrusion die.

Lapho isixazululiwe inkinga yokuklama, inqubo ebonakalayo yokukhipha iqala ukukhipha i-extrusion ngentambo ye-aluminium, induku yokuphonsa i-aluminium kumele ishiswe ngaphambi kokuyinciphisa, ukuthambisa okuhle izinduku zokuphonsa i-aluminium sheng ingot kufakwa emgqonyeni we-extruder ngaphakathi, bese kuthi phezulu amandla we-hydraulic cylinder acindezela u-extrusion rod, ingaphambili lenduku ye-extrusion inephedi yokucindezela, okushisa okufudumele okunjalo kwe-aluminium ku-dummy block ngaphansi kwengcindezi enamandla evela ekubunjweni ngokunemba ekubumbeni i-extrusion molding.

Nakhu okwenzelwe isikhunta: ukwakheka komkhiqizo odingekayo ekukhiqizeni.

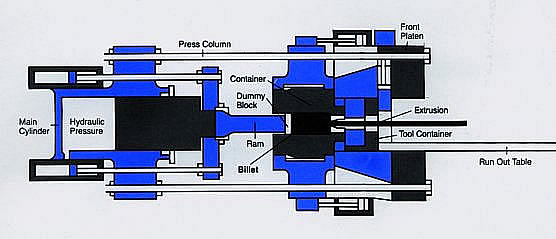

Isithombe sithi: umdwebo ojwayelekile ovundlile we-hydraulic extruder schematic

Ukuqondiswa kwe-extrusion kushiywe kwesokudla

Le ncazelo elula yokukhishwa okuqondile okusetshenziswa kakhulu namuhla. Ukukhishwa okungaqondile kuyinqubo efanayo, kepha kunomehluko obaluleke kakhulu.

Enqubeni engaqondile ye-extrusion.I-die ifakiwe kubha engenalutho ye-extrusion, ukuze i-die icindezelwe ibha ye-aluminium engenakususwa ingenalutho, iphoqa i-aluminium alloy ukuthi ikhishwe ibha engenalutho nge-die.

Eqinisweni, inqubo yokukhipha ifana nokucindezela umuthi wokuxubha. Lapho ingcindezi isetshenziswa ekugcineni okuvaliwe komuthi wokuxubha, umuthi wokuxubha oyindilinga uyakhanywa ngokuvula okuyindilinga.

Uma imbobo iyisicaba, umuthi wamazinyo ocindezelweyo uphuma njengeribhoni.

Vele, ukwakheka okuyinkimbinkimbi nakho kungakhanywa lapho kuvuleka isimo esifanayo.Isibonelo, abenzi bamakhekhe basebenzisa amashubhu abunjwe ngokukhethekile ukukhama u-ayisikhilimu ukwenza zonke izinhlobo zokuthakazelisa.

Ngenkathi ungeke ukwazi ukwenza imikhiqizo eminingi ewusizo ngomuthi wokuxubha noma u-ayisikhilimu, awukwazi ukukhama i-aluminium kumashubhu ngeminwe yakho.

Kepha ungasebenzisa umshini onamandla wokubacindezela ukukhipha i-aluminium ohlangothini olunikeziwe lwesikhunta ukukhiqiza imikhiqizo ehlukahlukene ewusizo cishe kunoma yisiphi isimo.

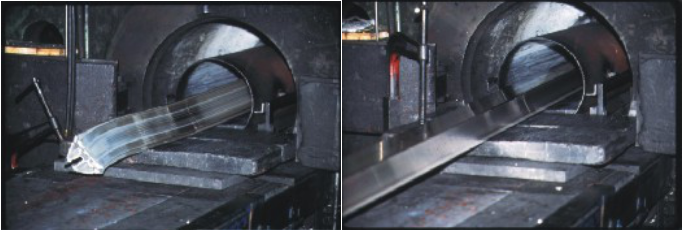

Isibalo esingezansi (kwesobunxele) sikhombisa isigaba sokuqala se-extruder ekuqaleni kwe-extrusion. (kwesokudla)

Ibha

Ibha ye-aluminium ayinalutho ngenqubo ye-extrusion. Ibha ye-aluminium esetshenziselwa i-extrusion ingaba eqinile noma engenalutho, imvamisa i-cylindrical, futhi ubude bayo bunqunywa yishubhu le-extrusion.

Izinduku ze-Aluminium zivame ukwenziwa ngokusakaza, noma ngokufaka noma ukufaka i-powder.Ivame ukwenziwa ngokusika imigoqo ye-aluminium alloy enokwakheka okuhle kwe-alloy.

Ama-aluminium alloys ngokuvamile akhiwa ngezinto ezingaphezu kwesisodwa zensimbi. Ama-alloys e-extruded aluminium akhiwe ngomkhondo (imvamisa awukho ngaphezu kwama-5%) wezinto (njengethusi, i-magnesium, i-silicon, i-manganese, noma i-zinc) ezithuthukisa izakhiwo ze-aluminium emsulwa futhi zithinte inqubo ye-extrusion.

Ubude benduku ye-aluminium buyahlukahluka kusuka kumkhiqizi kuye kumkhiqizi, okunqunywa ubude bokugcina obudingekayo, isilinganiso se-extrusion, ubude bokukhipha kanye nesabelo se-extrusion.

Ubude obujwayelekile ngokuvamile buqala ngamasentimitha angama-26 (660mm) kuye kuma-intshi angama-72 (1830mm). Amadayimitha wangaphandle aqala ngamasentimitha ama-3 (76mm) kuye kuma-intshi angama-33 (838mm), amayintshi ayi-6 (155 mm) kuya kuma-intshi ayi-9 (228 mm)

Inqubo eqondile ye-extrusion

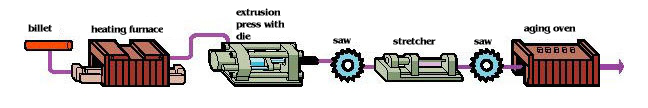

[billet] [ukufudumeza ifenisha] [umshini wokukhipha i-extrusion nge-die] saw [strecher] [ukuguga overn]

Umdwebo ukhombisa izinyathelo eziyisisekelo zokukhipha ibha ye-aluminium

Lapho ukuma kokugcina komkhiqizo kunqunywa, kukhethwa i-aluminium alloy efanelekile, ukukhiqizwa kwe-extrusion die kuqediwe, futhi ukulungiswa kwenqubo yangempela ye-extrusion kuyaphothulwa.

Bese ushisa ibha ye-aluminium nethuluzi le-extrusion. Ngesikhathi senqubo yokukhipha i-extrusion, ibha ye-aluminium iqinile, kepha isithambile esithandweni somlilo.

Iphuzu lokuncibilika kwe-aluminium alloy cishe liyi-660 ℃ .Izinga lokushisa elijwayelekile lenqubo ye-extrusion ngokuvamile likhulu kune-375 ℃ futhi lingaba phezulu ngama-500 ℃, ngokuya ngesimo sensimbi.

Inqubo yangempela ye-extrusion iqala lapho induku ye-extrusion iqala ukusebenzisa ingcindezi kwinduku ye-aluminium ku-ingot.

Imishini yokunyathelisa ehlukile ye-hydraulic yakhelwe ukukhama noma yikuphi ukusuka kumathani ayi-100 kuye kumathani ayi-15,000.Le ngcindezi ye-extrusion inquma usayizi we-extrusion okhiqizwa umshini we-extrusion.

Ukucaciswa komkhiqizo okwandisiwe kukhonjiswa ngosayizi omkhulu wesigaba somkhiqizo, kwesinye isikhathi nobubanzi bomkhawulo womkhiqizo.

Lapho i-extrusion isanda kuqala, ibha ye-aluminium iba ngaphansi kwamandla okuphendula kwesikhunta futhi iba mfushane futhi ibe mkhulu, kuze kube yilapho ukunwetshwa kwebha ye-aluminium kunqunyelwe udonga lwe-ingot barrel;

Bese kuthi, njengoba ingcindezi iqhubeka ikhula, insimbi ethambile (esamile ngokuqinile) ayinandawo yokugeleza bese iqala ukukhanywa iphume emgodini wokubumba kwesikhunta iye komunye umkhawulo wesikhunta, yakhe iphrofayli.

Cishe i-10% yenduku ye-aluminium (kufaka phakathi isikhumba se-aluminium rod) isele emgqonyeni we-ingot, umkhiqizo we-extrusion unqunywa kusuka kwisikhunta, futhi insimbi esele emgqonyeni we-ingot iyahlanzwa iphinde isetshenziswe kabusha. Ngemuva kokuthi umkhiqizo ushiye isikhunta, inqubo elandelayo ukuthi umkhiqizo oshisayo we-extrusion uyaqedwa, ngomshini futhi uneminyaka.

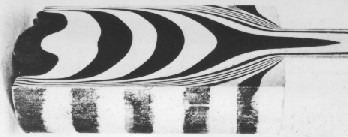

Lapho i-aluminium evuthayo ikhishwa esikhunjeni nge-ingot cylinder, insimbi maphakathi nebha ye-aluminium igeleza ngokushesha kunomphetho.Njengoba umugqa omnyama osemfanekisweni ukhombisa, insimbi ezungeze imiphetho ishiywa ngemuva ukuze iphinde isetshenziswe njenge insali.

Izinga le-extrusion lincike ekuxhunyweni kwengxubevange nokuma komgodi wokufa. Ukusebenzisa i-alloy enzima ukukhama izinto eziyinkimbinkimbi ezimile kungahamba kancane ngamamitha ayi-1-2 ngomzuzu.Ngama-alloys athambile, ukwakheka okulula kungakhanywa kumamitha ayi-180 ngomzuzu noma ngaphezulu.

Ubude bomkhiqizo we-extrusion buxhomeke kubha ye-aluminium kanye nomgodi wesikhunta. I-extrusion eqhubekayo ingaveza umkhiqizo ongafika ezinyaweni ezingama-200 ubude.I-extrusion yakamuva yokubumba, lapho umkhiqizo okhishiwe ushiya i-extruder ibekwa kwisilayidi (okulingana nebhande lokuhambisa);

Ngokuya nge-alloy ehlukile, ukukhishwa kwemodi yokupholisa komkhiqizo: kuhlukaniswe ukupholisa kwemvelo, ukupholisa umoya noma amanzi kepha kucima.Lesi isinyathelo esibalulekile sokuqinisekisa ukusebenza komkhiqizo ngemuva kokuguga.Umkhiqizo okhishiwe udluliselwa ku umbhede obandayo.

Qondanisa

Ngemuva kokucima (ukupholisa), umkhiqizo okhishiwe uqondiswa futhi uqondiswe nge-stretcher noma i-straightener (ukunweba kubuye kubekwe njengokusebenza okubandayo ngemuva kwe-extrusion) .Ekugcineni, umkhiqizo udluliselwa emshinini wokusaha ngomshini odlulisayo.

Isaha

Ukusawa okujwayelekile komkhiqizo kuqeda ukusikwa komkhiqizo kubude obuthile bezentengiselwano.Amasaha ayisiyingi asetshenziswa kakhulu namuhla, njengesaha zengalo ezijikelezayo ezisika izingcezu ezinde zezinto ezikhishiwe zibheka phezulu.

Kukhona namasaha asikiwe ukusuka phezulu kwephrofayili (njengesaha kagesi) Futhi itafula elibonwayo eliwusizo, itafula lesaha linensimbi yediski kusuka ezansi kuye phezulu ukusika umkhiqizo, bese kuthi isaha libuyele ezansi yetafula lomjikelezo olandelayo.

Isaha eliyindilinga eliqediwe elijwayelekile lingamasentimitha ayi-16-20 ububanzi futhi linamazinyo angaphezu kwe-100 e-carbide. Ama-blade saw saw asetshenziselwa ama-extruders amakhulu.

Umshini wokusika ozigcobayo unenqubo eletha i-lubricant ku-sawtooth ukuqinisekisa ukusebenza kahle kwe-sawing kanye nobuso besaha.

Umshini wokuzenzekelayo ugcina izigaba zisetshenziselwa ukusika futhi imfucumfucu yamasaha iqoqelwa ukusetshenziswa kabusha.

Ukuguga:

Eminye imikhiqizo ekhishiwe idinga ukuguga ukuze ithole amandla amakhulu, ngakho-ke ibizwa nangokuthi ukuguga.Ukuguga ngokwemvelo kuyenziwa ekamelweni lokushisa.Ukuguga okwenziwe ngokwenziwa kwenziwa esithandweni sokuguga.Ngokobuchwepheshe, kubizwa ngokuthi ukwelashwa kokushisa kwesigaba esinamandla.

Lapho iphrofayli ikhishwa kudruder, iphrofayli iba yi-semi-solid.Kodwa ngokushesha iyaqina lapho ipholile noma icishiwe (noma ipholile emoyeni noma ipholile ngamanzi).

Ama-alloys e-aluminium angaphathwa ngokushisa (njengama-aluminium alloys ane-magnesium eyengeziwe noma ama-manganese) aqiniswa ukuguga kwemvelo nokusebenza okubandayo.I-alloy alloy alaphekayo (njenge-aluminium alloy enethusi, i-zinc, i-magnesium + i-silicon) ingathola amandla nobulukhuni ngokuthinta ukwelashwa kokushisa kwesakhiwo se-alloy metallographic.

Ngaphezu kwalokho, ukuguga ukwenza izinhlayiya zesigaba esiqinisiwe zihlukaniswe ngokulinganayo ukuthola amandla amakhulu wesivuno, ubulukhuni nokuqina kwe-alloy ekhethekile.

Bales

Noma ngabe ukuguga kwesithando somlilo noma lokushisa ekamelweni lokuguga, ngemuva kokuguga okugcwele, iphrofayli idluliselwa ekwelashweni komhlaba noma ekuqhutshweni okujulile kokusebenzela noma emabhaleni alungele ukuthuthwa kumakhasimende.

Abantu nabo bayabuza

Isikhathi Iposi: Mar-20-2020