Umkhuba owodwa esiwubonayo ukuthi i-aluminium noma i-aluminium extrusionisetshenziswa kakhulu ezimbonini ezahlukahlukene. Ukusetshenziswa kwe-aluminium extrusion kungafinyelela ekwehliseni izindleko okungalindelekile nokwehlisa isisindo.

Ngokuqonda ngokugcwele inqubo, ukufa, izici nokusetshenziswa kwe i-aluminium extrusion singakwazi yini ukuklama ukukhishwa kwe-aluminium (amagobolondo e-aluminium extrusion, imikhiqizo egobile ye-aluminium extrusion, aluminium extrusion amagobolondo kagwayi kagesi, aluminium extrusion ugesi amagobolondo, ukukhishwa kwe-aluminium, Cindezela amagobolondo eselula, amagobolondo e-aluminium extrusion ekhompyutha, i-aluminium extrusion radiators, njll.) ukuqinisekisa ikhwalithi ephezulu nezindleko eziphansi zokukhishwa kwe-aluminium.

01

Incazelo yenqubo ye-aluminium extrusion

Aluminium extrusion udini. Ukuze uthole ukwakheka okudingekayo kwesigaba esiphambanweni, usayizi kanye nezakhiwo ezithile zomshini wengxenye noma indlela esezingeni eliphansi yokucubungula ipulasitiki.

02

Aluminium extrusion die

Konjiniyela bokuklanywa komkhiqizo, yize singeke sidizayine i-aluminium extrusion iyafa, siyazi isakhiwo esiyisisekelo se-extrusion die kanye nendlela yokusebenza kwamaphrofayili ahlukile we-extrusion, okusiza ukwandisa ukwakheka kwezingxenye ze-extrusion. Nciphisa izindleko zesikhunta futhi uthuthukise ukusebenza kahle kokukhiqizwa kwezingxenye ezikhishiwe.

2.1 Kuyini ukukhishwa kwe-extrusion?

I- extrusion kufaempeleni kuyidiski eyinsimbi eyindilinga, kufaka phakathi ukuvuleka okukodwa noma ngaphezulu ukwakha iphrofayili oyifunayo. Imvamisa zenziwe ngensimbi ye-H-13 die futhi ziphathwe ukushisa ukumelana nengcindezi nokushisa kwe-aluminium eshisayo njengoba idlula kofayo.

Yize i-aluminium ibukeka ithambile, ukusunduza i-aluminium ingot (engenalutho) nge-porous aluminium extrusion encane eyakhiwe ukwakha umumo oyifunayo kudinga ingcindezi enkulu.

2.2 Ukuhlukaniswa kwe-extrusion kuyafa

Ngokuya ngesimo esinqamulelayo se-aluminium extrusions, isikhunta esihambisanayo sehlukaniswe ngezinhlobo ezintathu: okuhlanganisiwe, okuwumgogodla, nokungenalutho. Phakathi kwazo, isikhunta esiyize sinesakhiwo esiyinkimbinkimbi kunazo zonke, kulula ukusigqoka nokuphuka, futhi sinezindleko eziphakeme kakhulu.

2.3 Impilo ye-extrusion iyafa

Lapho kuklanywa ukukhishwa kwe-aluminium, ukuqongelela ukushisa nengcindezi engalingani (njengodonga oluncane, ukujiya kodonga olungalingani, nezici ezivelele) ngababulali abakhulu be-extrusion die life.

Onjiniyela abangochwepheshe be-extrusion mold bangaklama isikhunta ukulawula ukucindezela okushisayo nokungafani, ukunciphisa isivinini se-extrusion ukunweba impilo yesikhunta, kepha ekugcineni isikhunta kufanele sithathelwe indawo.

Ngaphambi kokuklama ukukhishwa kwe-aluminium, onjiniyela bokwakhiwa komkhiqizo kufanele baqonde ukuthi yiziphi izici zokuklama ezizothinta kakhulu izindleko zokucubungula. Uma kunokwenzeka, ukushintsha ukwakheka kwesigaba sezingxenye ze-aluminium extrusion, ukusetha ukubekezelelana okufanele, nokukhetha izinto ezifanele ze-aluminium alloy kungonga izindleko zokucubungula zesikhunta se-aluminium extrusion.

03Izinzuzo zenqubo ye-aluminium extrusion

1) Iyahlala

Ukumelana nokugqwala, ukumelana nokugqwala nokumelana nesimo sezulu kwe-aluminium kungenye yezinzuzo zayo ezibaluleke kakhulu. I-Aluminium ingagqwala ngokwemvelo futhi imelane nokugqwala ngaphandle kokwelashwa okwengeziwe. Lokhu kungenxa yobukhona befilimu evikelekile, eyakhiwe ngokwemvelo ye-aluminium oxide ebusweni bayo. Ngokufaka i-anodizing, ukumelana kwayo nokugqwala kuyaqina.

Isibonelo, endaweni engaphandle, ama-anodizing angama-25-micron angathuthukisa ukumelana nokugqwala futhi athuthukise ukuphela komhlaba. Ngaphezu kwalokho, i-aluminium ayidingi ukugcinwa, futhi ezimweni eziningi asikho isidingo sokukhathazeka ngokugqwala.

2) Ilula futhi inamandla

I-Aluminium ilula ngaphezu kwensimbi engama-33%, kepha isagcina amandla ayo amaningi. Amandla aqine kakhulu ama-alloys amaningi e-aluminium aphakathi kwama-MPA angama-70-700, futhi ukuminyana kungaphansi kokuthathu kokungaphansi kwensimbi.

Onjiniyela bokwakha umkhiqizo akudingeki bakhathazeke ngamandla wezingxenye ze-aluminium extrusion. Zingasetshenziswa njengezingxenye zokwakhiwa embonini yezokwakha kanye nasembonini yezimoto, futhi ziyizinto ezingcono kakhulu ezingangena esikhundleni sezinye izinto zensimbi. Ukuze wehlise isisindo futhi wehlise ukusetshenziswa kwamandla, imboni yezimoto isebenzise kakhulu ama-aluminium alloys.

3) Ukuqhuba okuhle kokushisa

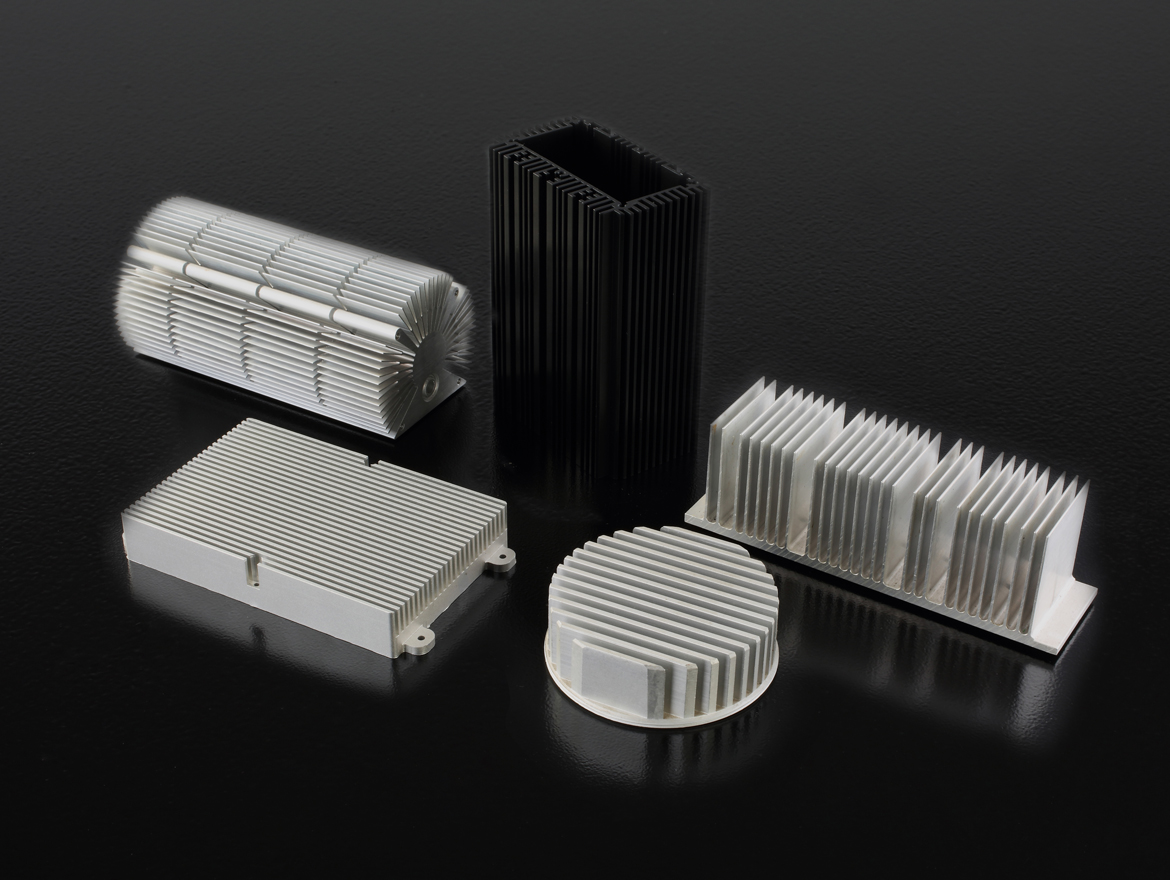

Ukuhanjiswa kwe-aluminium okushisayo kufana kakhulu nethusi, kepha isisindo silula kakhulu.

I-Aluminium ingumqhubi wokushisa omuhle kakhulu, futhi ukwakheka kwephrofayili kwe-aluminium extrusion kungakhulisa indawo engaphezulu yokuqhuba ukushisa futhi yakhe isiteshi sokushisa. Isibonelo esijwayelekile isinki yokushisa ye-CPU, ne-aluminium isetshenziselwa ukushabalalisa ukushisa kwe-CPU. I-Aluminium extruded radiator ingumkhiqizo omuhle kakhulu ongawusebenzisa.

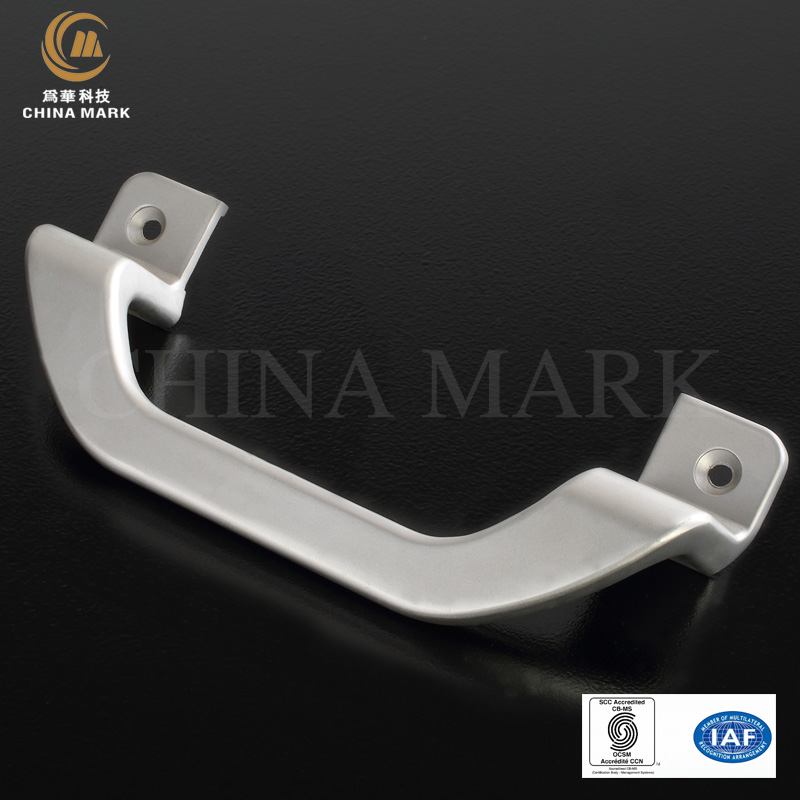

4) Ukubukeka kwemfashini

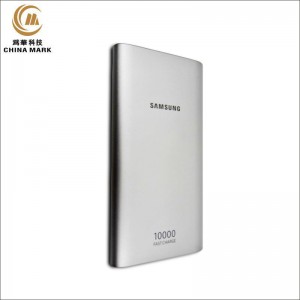

I-aluminium ekhishiwe ingapendwa, ifakwe i-electroplated, ipholishwe, futhi ifakwe i-anodized, enikeza onjiniyela ithuba lokukhetha okubanzi kunezinye izinto. Isibonelo: Isibambo se-Aluminium extrusion

5) Ibanga lesicelo elibanzi

Ngokuyinhloko, noma yikuphi ukwakheka okunqamulelayo kungakhiwa nge-aluminium extrusion, ngakho-ke uhla lwesicelo se-aluminium extrusion lubanzi kakhulu. Onjiniyela bangakha izingxenye ezahlukahlukene ukuhlangabezana nezidingo zezindawo ezahlukahlukene zohlelo lokusebenza.

6) Ukucubungula okulula kwesibili

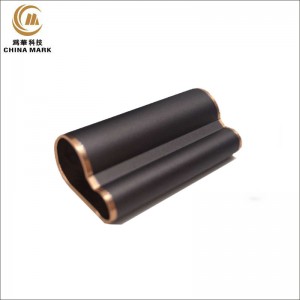

Ukukhishwa kwe-Aluminium kulula ukuyakha, ukusika, ukubhola, inqubo, isitembu, ukugoba kanye ne-weld ukuze ihambisane nezinhloso ezithile. Isibonelo: ojantshi be-aluminium extrusion, njll.

7) iDemo isikhunta ukucutshungulwa umjikelezo kanye nezindleko eziphansi

I-aluminium extrusion die ilula, umjikelezo wokucubungula ufushane, futhi izindleko ziphansi. Lokhu ukuqhathanisa phakathi kwe-AEC aluminium extrusion nezinye izinqubo, ukubhekisela kuphela.

8) ukuncela umthelela kanye nokusonteka

Ukuphuma kwe-Aluminium kuyamelana nokuguquguquka okubangelwa ukunyakaza kwesimo sezulu nokwakhiwa. Izimoto zingathatha amandla omthelela. Izingxenye ze-Aluminium ezikhishiwe zigcina amandla nokuzivumelanisa nezimo ngaphansi komthwalo kanye nokubuyela emuva kumthelela. Isibonelo: ukusetshenziswa kwezimotoukukhishwa kwe-aluminium. Ukusetshenziswa kokukhishwa kwe-aluminium yezimoto kungathatha amandla omthelela

9) Ukuvikelwa kwemvelo

I-Aluminium iyinto enobungani bemvelo futhi kulula ukuyisebenzisa kabusha.

Ngemuva kokuhlunga nokwabelana ngama-athikili angenhla, manje sesinokuqonda kwe-aluminium extrusion, imikhiqizo ye-aluminium extrusion, i-aluminium extrusion control yezinombolo, isikhunta se-aluminium extrusion, njll. izimpawu ezikhishwe kanye nokuvalelwa kwe-aluminium okukhishiwe. Sicela unake ikhasi lethu eliyisiqalohttps://www.cm905.com/.

Isikhathi Iposi: Aug-10-2021