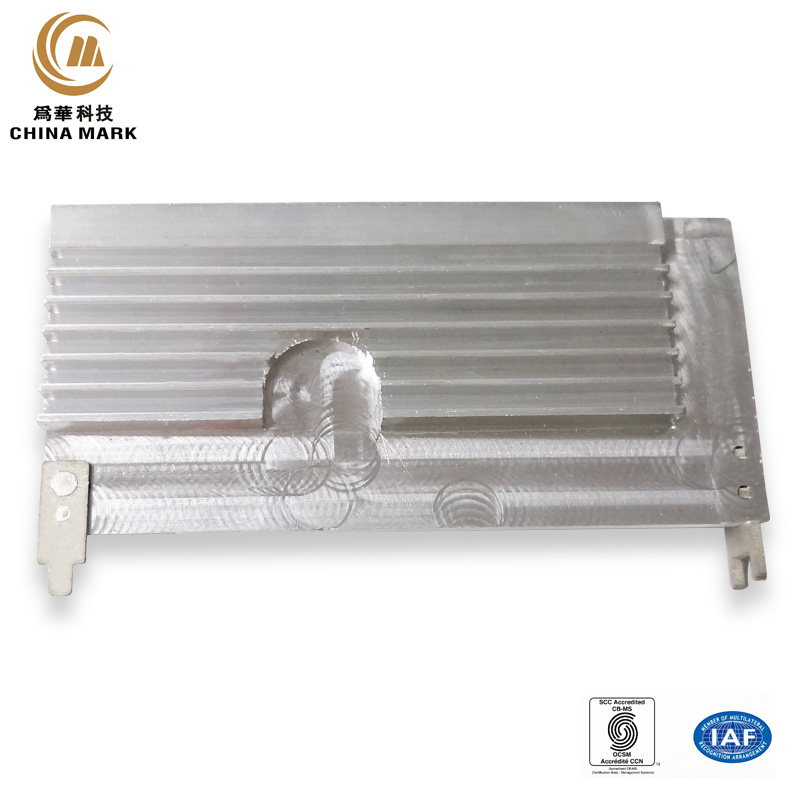

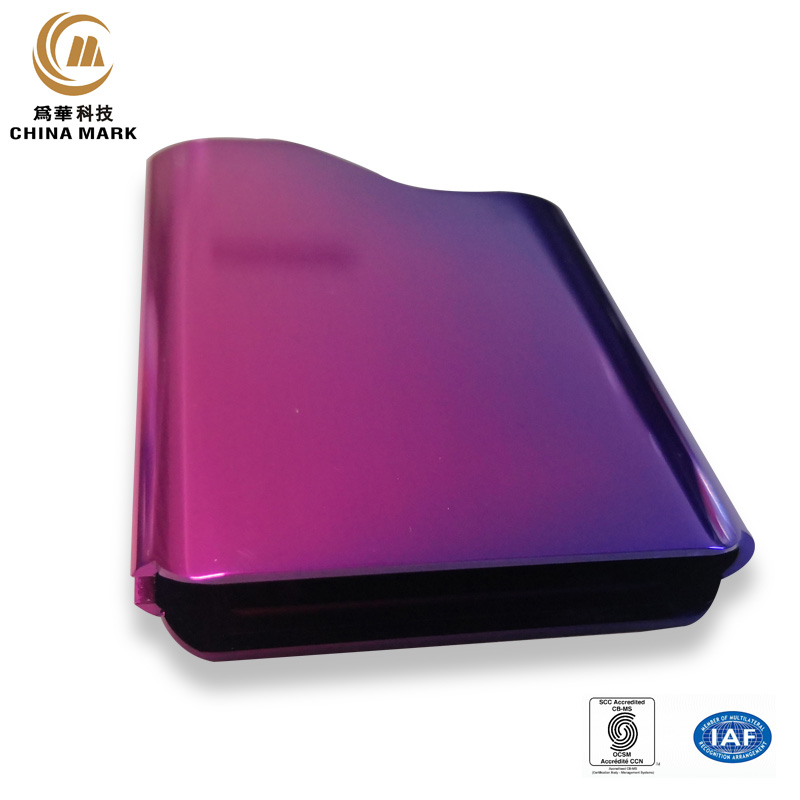

Aluminium extrusion: Ingabe i-aluminium alloy (deformation) ingot extrusion inqubo yokubumba ne-extruder.

Ubuchwepheshe be-Aluminium alloy extrusion

Ukuhlukaniswa kwezingxenye ezikhishiwe:

Isigaba esiqinile: azikho izimbobo esigabeni.

Iphrofayili engenalutho: isigaba sephrofayela sinezimbobo.

Isakhiwo nokuklanywa kwe-extrusion elula okulula:

Tube single extrusion die zimbili: eyokuqala i-extrusion eqinile die.The yesibili iphrofayili engenalutho extrusion die.The isakhiwo ethize kanje:

1) umgqomo we-extrusion: umzimba ongoqweqwe owenziwe ngensimbi enamandla kakhulu, ongasuswa ngentambo yangaphakathi.Ubude bunqunywa ngokuya nge-extruder tonnage.Izinto: ijazi 5CrMnMo, isethi yangaphakathi 3Cr2W8V.

2) ukwesekwa kwesikhunta: qinisekisa ukuthi isikhunta nephedi lesikhunta kugxilile, ukufaka isikhunta, isikhunta pad amathuluzi asizayo.

I-3) i-die pad: i-die pad ne-die zinosayizi ofanayo, ubukhulu bayo izikhathi ezi-3 zobukhulu bokufa, futhi zithwala ingcindezi ye-extrusion kanye ne-die.Die pad, usayizi womgodi wokufa mkhulu kancane kunesikhunta. : ingxubevange yethuluzi lensimbi.

4) cindezela umlomo: amathuluzi asizayo aqinisekisa ukuthi isikhunta asigudluki ngesikhathi se-extrusion futhi sihambisana kakhulu nomgqomo we-extrusion. Isakhiwo nosayizi kunqunywa ngokuya ngobukhulu be-extruder.

I-5) i-extrusion gasket: ithuluzi elisizayo lokuvimbela ukuxhumana okuqondile phakathi kwe-shaft ye-extrusion nensimbi ekhishiwe.Ububanzi bayo bangaphandle bungaphansi kobubanzi obungaphakathi bomgqomo we-extrusion, futhi ubukhulu bayo buphakathi kuka-40 mm no-150mm.

6) i-extrusion shaft: lapho i-extrusion shaft isebenza, ingena kusilinda se-extrusion kanye noxhumana nabo ngephedi ye-extrusion. I-extrusion bearing ibhekene nengcindezi enkulu ye-extrusion ye-extruder.Izinto ezibonakalayo: 3Cr2W8V.

Isimiso sokumiswa komgodi wokufa:

Ukucushwa komgodi womgodi ongashadile owodwa: imvamisa ukwenza isikhungo sesikhunta samandla adonsela phansi nesikhunta sivumelane.Uma ubukhulu bodonga buhluka kakhulu, ingxenye ye-thinnest kufanele ihlelwe maphakathi nesikhunta.

Ukumiswa kwephrofayili ye-porous hole hole: kwesigaba esincane noma ukulinganisa kwesigaba kubi, kuvame ukusetshenziswa isikhunta se-porous.Isikhala phakathi kwezimbobo zesikhunta esibi asifanele sibe sincane kakhulu.

Ukunqunywa kwebhande lokusebenza lomgodi wokufa:

1) thatha isigaba sonke njengebhentshimakhi, lapho ubude bomugqa wokusebenza (izikhathi ezi-1.5 kuye kwezi-2) zobukhulu bomkhiqizo ophelile.

2) ubude bebhendi elisebenzayo elincikene nephoyinti lobude ubude bebhanti elisebenzayo endaweni yokubhekisa kanye no-1mm.

3) ngogqinsi olufanayo, ubude bomugqa osebenzayo ebangeni elifanayo ukusuka maphakathi nesikhunta kuyafana.

4) ukuqala maphakathi nesikhunta, ukwanda nokwehla kobude bokusebenza kwebanga ngalinye le-10mm kungadluliselwa ezincwadini ezifanele.

5) imimese engenalutho ebhande elisebenzayo: imimese eminingi kakhulu engenalutho izothena amandla ebhande elisebenzayo lesikhunta.

Vimba i-engela:

Lapho ubude bomugqa wokusebenza womgodi wokufa bungaphezu kwe-15 kuye ku-25mm, empeleni, insimbi ayisalingani nomugqa osebenzayo ngenxa yokuncipha kosayizi, ngalesi sikhathi, isilinganiso sokugeleza kwensimbi singalungiswa yi-Angle yokuvimba. I-Angle phakathi kwebhasi kanye nolayini wesikhungo se-extrusion webhande elisebenzayo yi-Angle yokuvimba, futhi i-Angle yokuvimba esebenza kahle ngama-degree ama-3 kuye kwayi-5.

I-Flow Angle: imvamisa, i-Angle yokugeleza iyisigaxa esilinganayo noma isigaxa esithandele ekugcineni kobuso bokusebenza kwesikhunta.

Lokhu okungenhla kumayelana nokuthi isingeniso esihlobene nobuchwepheshe be-aluminium extrusion kanye ne-aluminium extrusion; Singabachwepheshe ukwenziwa kwe-aluminium extrusion amabhizinisi, anganikeza: i-arc aluminium extrusion, unxantathu i-aluminium extrusion nezinye izinsizakalo zokuphrinta ezenziwe ngokwezifiso; Siyakwamukela uthintane ~

Isikhathi Iposi: Apr-11-2020