Precision machining inqubo yokususa okokusebenza ku-workpiece ngesikhathi sokuqedela esigcina ukubekezelelana okuseduze.Kunezinhlobo eziningi zemishini yokunemba, kufaka phakathi ukugaya, ukuguqula kanye nokukhipha imishini.

Ukuphumelela ngokunemba ngemishini kudinga ikhono lokulandela amapulani akhetheke kakhulu akhiqizwe yidizayini esizwa yikhompiyutha (i-CAD) noma izinhlelo ezikhiqizwa yikhompiyutha (CAM) .Lobu buchwepheshe be-machining be-CNC bungadala amashadi e-3D noma Izinhlaka zokukhiqiza imishini, izinto noma amathuluzi. kumele yakhelwe ukuqinisekisa ikhwalithi nempumelelo.

Imishini yokwenza kahle ingasebenzisa izinto ezahlukahlukene, ezifana ne-bronze, ingilazi, i-graphite, ama-plastiki, insimbi nezinye izinsimbi.Ngokuya ngosayizi wephrojekthi nezinto ezisetshenziswayo, kuzosetshenziswa amathuluzi namasu wokunemba ahlukahlukene. imishini yokwenza ngokunemba kumele ibe nekhono futhi inolwazi kulezi zinqubo ezahlukene kanye nemishini.Ingasebenzisa noma iyiphi inhlanganisela yemishini yokumba, imishini yokugaya, imishini yokugaya, imishini yokugaya, amasaha kanye namarobhothi ashesha kakhulu ukwenza umsebenzi wenziwe.

Izinto ezisetshenziswa ku-CNC machining:

Ama-alloys weTitanium (Ti - 6 al4v)

I-Metal Matrix Composites MMC (AMC225xe)

Ama-Special Steels (300 m, Maraging 300-350, 15 cdv6, 17-4 PH nokunye)

Ama-aluminium alloys (2014, 2024, 6082, 7050, 7075 namanye), insimbi neCopper

ISuperalloys (Inconel 625 no-718)

Izinhlobo zemikhiqizo enemba:

1. Prototype kanye nomklamo ngokwezifiso

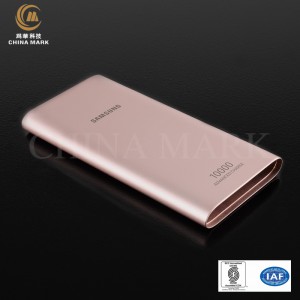

2. Imikhiqizo ye-elekthronikhi

3. Ukwelashwa okukodwa kanye nokungafaki

4, ezokuxhumana ngocingo,

5. Ezimboni kanye ne-OEM

6. Ubakaki wokufaka, idivaysi engaguquki, into enemba kahle, igobolondo nengxenye, umugqa wensimbi kanye nokwakheka konke kuyimikhiqizo ejwayelekile ekhiqizwa inqubo eyenziwe ngokwezifiso ye-CNC.

Mayelana ngokunemba yethu inkonzo machining

Izinzuzo eziphambili ze-CNC ngokunemba kwemishini zifaka phakathi amandla wokukhiqiza izingxenye eziyinkimbinkimbi ngokunemba okuphezulu ngenkathi kugcinwa izindleko zokukhiqiza nezokufaka eziphansi.

Imishini ye-CNC ubuchwepheshe obunokwethenjelwa futhi obuthuthukiswe ngokuphelele obususa kakhulu kungenzeka kwephutha lomuntu futhi ngaleyo ndlela busize ekuthuthukiseni ukunemba okuphelele.Ngaphezu kwalokho, ngokukhulula isikhathi so-opharetha ngesikhathi sokukhiqiza, ukunakwa kungagxila ekuqinisekisweni kwekhwalithi nasekuhlinzekeni ukwengamela iphrojekthi, okuyinto kusiza ukuqinisekisa ukuthi izidingo eziningiliziwe zenqubo yokukhiqiza ziyafinyelelwa.

Ngokuya kokunciphisa izindleko, i-CNC machining ayinciphisi izindleko kuphela ngokunciphisa isidingo sabasebenza abanamakhono, kepha futhi inciphisa inani eliphelele lezinto ezisetshenzisiwe.

Ngokunemba Okugcwele CNC machining

Sinikezela ngezinsizakalo ezigcwele ze-CNC zemishini yakho konke ukunemba kokugaya, izihlakala, ukucwila kokufa, imishini emincane kanye nezidingo ezijwayelekile.Umnyango wobunjiniyela Usebenzisa ukwakheka kwakamuva kwe-CAD / CAM nobuchwepheshe bokusebenzisana namakhasimende ethu.

Umklamo osizwa ngekhompyutha nokukhiqizwa

Sihlala sithuthukisa futhi sitshala imali kubuchwepheshe bethu nakwimishini ukunika amandla onjiniyela bethu ukuthi baklame umsebenzi onzima ukuze bahlangabezane nezidingo ezidinga kakhulu onjiniyela bethu bahlinzekwe ngezixazululo ze-3D zokumodela kanye ne-CAD / CAM ezisenza sikwazi ukuletha imiphumela enembile.

Ungancika kukhwalithi

Sazisa ikhwalithi.Sizibophezele ekunikezeni imikhiqizo nezinsizakalo ezihlangabezana noma ezidlula okulindelwe ngamakhasimende.Sihlala sifuna izindlela zokwenza ngcono uhlelo lwethu lokuphathwa kwekhwalithi

Yize iningi CNC ngokunemba machining ilungele ukucutshungulwa kwensimbi, la mathuluzi asebenziseka ngezindlela eziningi ngokweqile futhi angasetshenziswa ukukhiqiza okwenziwe ngezifiso izingxenye ngokunemba ngezimboni ezahlukahlukene.Siyakwamukela uxhumane nathi