Process characteristics of aluminum extrusion

1. During the extrusion process, the extruded metal can obtain a more intense and uniform three-way compression stress state in the deformation zone than rolling forging, which can give full play to the plasticity of the processed metal itself;

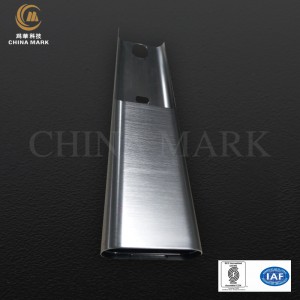

2. Extrusion molding can produce not only rods, tubes, shapes, and wire products with simple cross-sectional shapes, but also profiles and tubes with complex cross-sectional shapes;

3. Extrusion molding has great flexibility. It only needs to replace the extrusion tools such as molds to produce products with different shapes, specifications and varieties on one equipment. The operation of replacing extrusion molds is simple, fast, time-saving and efficient;

4. The precision of extruded products is high, the surface quality of the products is good, and the utilization rate and yield of metal materials are improved;

5. The extrusion process has a good effect on the mechanical properties of the metal;

6. The process flow is short and the production is convenient. One-time extrusion can obtain an overall structure with a larger area than hot die forging or forming rolling. The equipment investment is low, the mold cost is low, and the economic benefit is high;

7. Aluminum alloy has good extrusion characteristics, and is particularly suitable for extrusion processing. It can be processed by a variety of extrusion processes and a variety of mold structures.