The following introduces the main types of metal signs we manufacture:

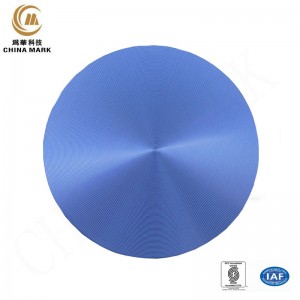

(1) Aluminum nameplate

The production process is often stamping, forging, brushing, printing, anodizing, sandblasting, etc. Aluminum is chemically resistant, highly recyclable, lightweight and durable. It is suitable for indoor and outdoor use.

The application of aluminum to various finishes (such as texture and selective gloss) is very coordinated to enhance brand awareness or convey graphic text in an attractive way.

Several basic processes of aluminum signs:

Screen printing: The screen printing equipment is simple, easy to operate, easy to print and plate making and low cost, the quality of the pattern details is extremely high, and the adaptability is strong.

Anodizing: It is mainly the anodizing of aluminum, which uses electrochemical principles to form a layer of Al2O3 (aluminum oxide) film on the surface of aluminum and aluminum alloy. This oxide film has special characteristics such as protection, decoration, insulation, and abrasion resistance.

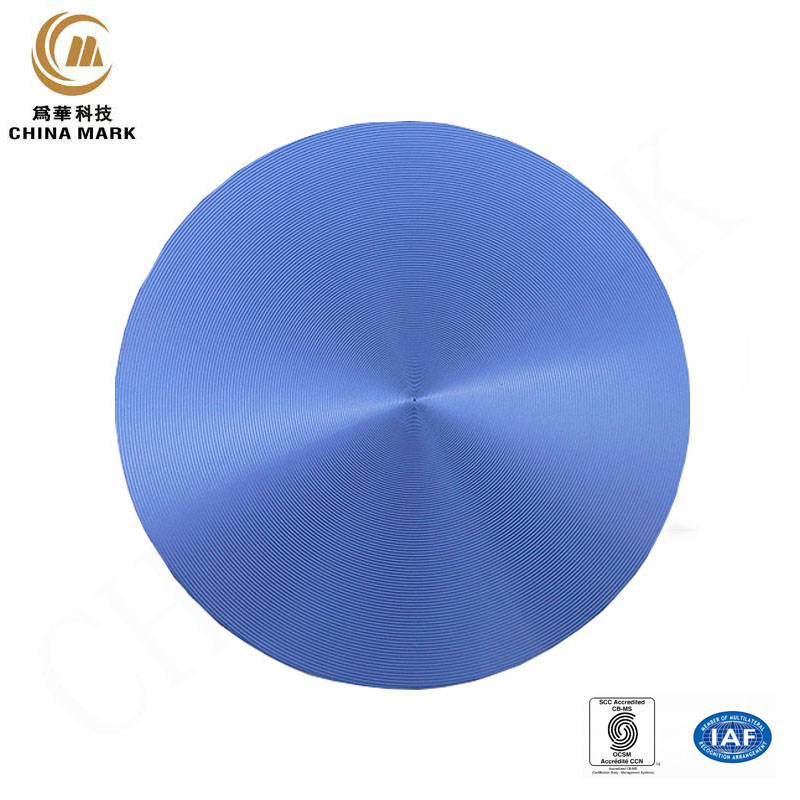

CD texture processing, processing all kinds of hardware, aluminum sheet, copper sheet, steel sheet, mobile phone case, digital camera case, MP3 case, nameplate and other surface treatments, car CD pattern, car inner and outer circle, lens cover, high-gloss inversion of rotating parts angle.

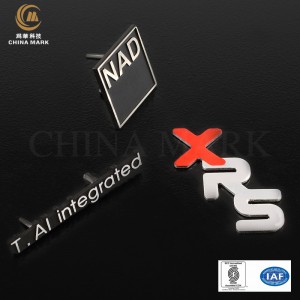

(2) Stainless steel nameplate

The production process is often stamping, etching or printing. It is cost-effective and caters to the trend. It has abrasive yarn corrosion and its high-gloss process. In addition, it uses a strong adhesive to paste, which is very convenient to use. The stainless steel sign has a metallic texture, a high-end feel, and is lighter, showing a stylish and modern quality. Stainless steel texture is durable, very suitable for outdoor products

Stainless steel nameplates and decorative strips are expected to be used in almost any environment for many years. It is corrosive and resistant to dents. Its strength makes it very suitable for industrial data or nameplates and information labels.

Several basic techniques of stainless steel signs:

Electroplating process: the process of using electrolysis to attach a layer of metal film to the surface of the parts, thereby preventing metal oxidation, improving wear resistance, conductivity, light reflection, corrosion resistance and enhancing aesthetics.

Stainless steel etching:

It can be divided into shallow etching and deep etching. The shallow etching is generally below 5C. The screen printing process is used to form the etching pattern! Deep etching refers to the etching with a depth of 5C or more. This kind of etching pattern has obvious unevenness and has a strong feel to the touch. Generally, the photosensitive etching method is used; because the deeper the corrosion, the greater the risk, so The deeper the corrosion, the more expensive the price!