Okokuqala, ndiza kucacisa intsingiselo yoshicilelo lwesikrini ngokufutshane?

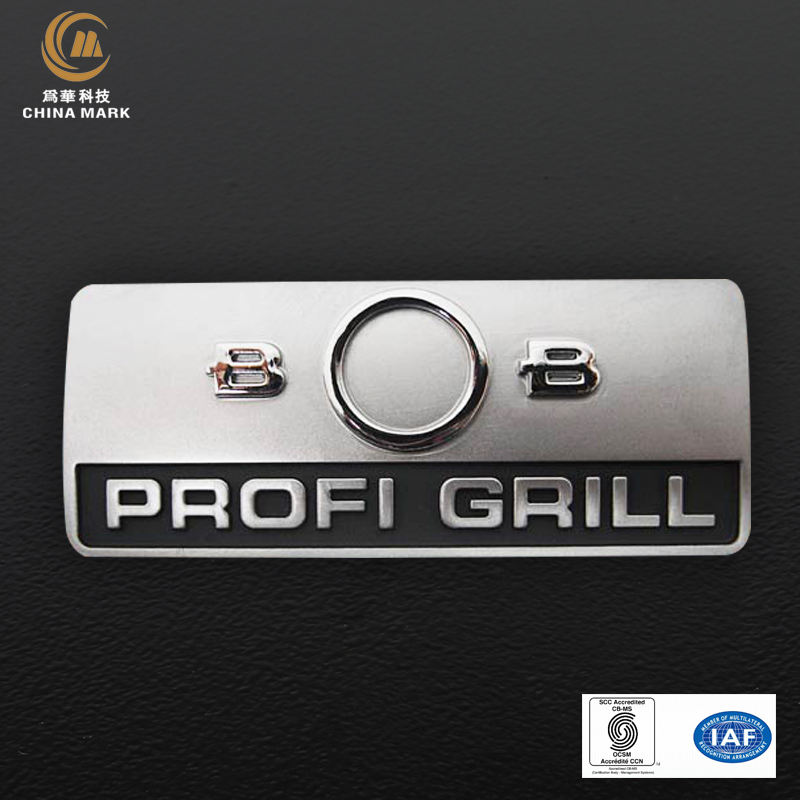

Ushicilelo lwesikrini, olukwabizwa ngokuba lushicilelo lwesikrini, lubhekisa kwinkqubo apho ipleyiti yoshicilelo yesikrini enemifanekiso kunye nesicatshulwa yenziwe ngokusebenzisa isikrini njengesiseko sepleyiti nangendlela yokwenza i-photosensitive plate-making.

1. Zeziphi izinto ezinokusetyenziswa ukwenza iilebhile zelineplate yesikrini sesilika?

A. Aluminiyam, intsimbi engatyiwa kunye neminye imiphezulu yesinyithi;

B. I-Soft kunye ne-PC eqinile, i-PET, i-PVC i-plastic parts surface;

2. Yintoni ukutyeba ngokubanzi kwesikrini sesilika yepleyiti yegama lentsimbi?

Ngokubanzi 0.3mm-2.0mm

3. Zeziphi izinto eziphambili ezinokuprintwa kwiimpawu zesikrini sesilika?

Inokushicilela zonke iintlobo zeepateni ezilula okanye ezintsonkothileyo, isikrini sesilika kuzo zonke iintlobo zombhalo, i-LOGO, iwebhusayithi njalo njalo.

4. Zeziphi iziphumo zenkqubo enokwenziwa ziimpawu zesilika-screen?

Ngokubanzi, iipleyiti zoshicilelo ezichwetheziweyo, iimpawu zoshicilelo ezixutyiweyo, iimpawu zoshicilelo lwe anode zinokwenziwa.

5. Ziziphi iingenelo zeempawu zesikrini sesilika?

(1) Ayikhawulelwanga bubungakanani kunye nokumila kwe-substrate

(2) Ukwenziwa kweepleyiti kulula, ixabiso liphantsi, kwaye kulula ukuyiqonda le teknoloji

(3) Ukubambelela okuqinileyo

(4) Imibala etyebileyo

6. Ziphi iimpawu zoshicilelo lwesikrini ezisetyenziswa kakhulu?

Iimpawu zoshicilelo lwesikrini zisetyenziswa kakhulu njengemiqondiso yokonwabisa izixhobo zomculo zombane, iimpawu zefenitshala, iimpawu zoomatshini boshishino, iimpawu zendlela, njl.

Ke yeyiphi inkqubo imiqondiso yoshicilelo lwesikrini eyenziwe ngayo?

Ukuze kuphunyezwe iimpawu zesilika-screen ekungekho lula ukuwa kunye nokuphelelwa, ngoko kufuneka senze unyango olulula kumphezulu wesinyithi phambi kokuba siprinte kwintsimbi.

Eyokuqala unyango degreasing, nto leyo esusa i-inki phezu komhlaba metal, nto leyo enokwandisa ukuncamathela inki, ukwandisa ukuqina, ukwandisa ukuxhathisa ukukhuhlana kunye nokudinwa, kwaye wenze i-inki eprintiweyo ingabi lula ukucima.

Isinyathelo esilandelayo kukususa ifilimu ye-oxide.Ekubeni isinyithi silula ukwenza ifilimu ye-oxide emva kokuqhagamshelana nomoya, kwaye ifilimu ye-oxide kulula ukusabela ngayo kunye ne-asidi kunye ne-alkali, okukhokelela ekunamatheleni kwe-inki embi, ngoko ke ngaphambi kokushicilela, sebenzisa i-asidi ye-sulfuric okanye i-hydrochloric acid ukulungiselela isisombululo se-dilute. phambili.Xa uqatywe phezu komphezulu wesinyithi we-oxide layer, kulula ukwenza umaleko we-oxide uwe kwaye uphucule ukunamathela kwi-inki yoshicilelo.

Emva kokwenza oku, unokukhetha intsimbi ecocekileyo kwaye wenze la manyathelo alandelayo ngokulandelelana:

Izinto zokulungiselela - ukusetwa kombhalo-ngqangi - imveliso yefilimu - ushicilelo - ukwenza imveliso ngokuzenzekelayo - ukwenza imveliso eyenziwe ngesandla - ukuhlolwa okupheleleyo - ukupakishwa kunye nokuthutha

Ekugqibeleni, uphawu lwesikrini sesilika lugqityiwe.

Ukuba ukhangele uphawu oluthembekileyo lwe-aluminium okanye uphawu lwensimbi engenasici, uphawu lobhedu, umenzi wesignali ye-nickel, wamkelekile ukuba uqhagamshelane nathi.Ubuchwephesha bethu bukwenza ukuba ufumane umgangatho ophezulu, uphawu olufikelelekayo kunye nexesha elifutshane lokuhambisa.

Ukuba sele unayo ekhoyoumenzi weplate yegama, wamkelekile kakhulu ukuba uqhagamshelane nathi.Unokusisebenzisa njenge-backup yakhoabenzi nameplate metal, njengeinkampani nameplatengexabiso kunye nothelekiso lwesampulu, kwaye ngokucothayo wakhe ukuthembela kwaye ukholelwe ukuba singakunika uxolo lwengqondo

Uphendlo olunxulumene nelogo yealuminiyam:

Funda ngakumbi iindaba

Ividiyo

Ixesha lokuposa: Mar-11-2022